White Cross Bay

For a map depicting the location of White Cross Bay, please click here

For a plan of the site – Medway Archives Centre, please click here. This plan includes the location of 3 mooring buoys, as depicted in this photo.

With the prospect of the Sunderland flying boat factory at Rochester of Short Brothers (Rochester & Bedford) Ltd being bombed, the Ministry of Aircraft Production determined in 1940 to disperse part of production.

Reasons for a Short Sunderland flying boat factory being built at Windermere

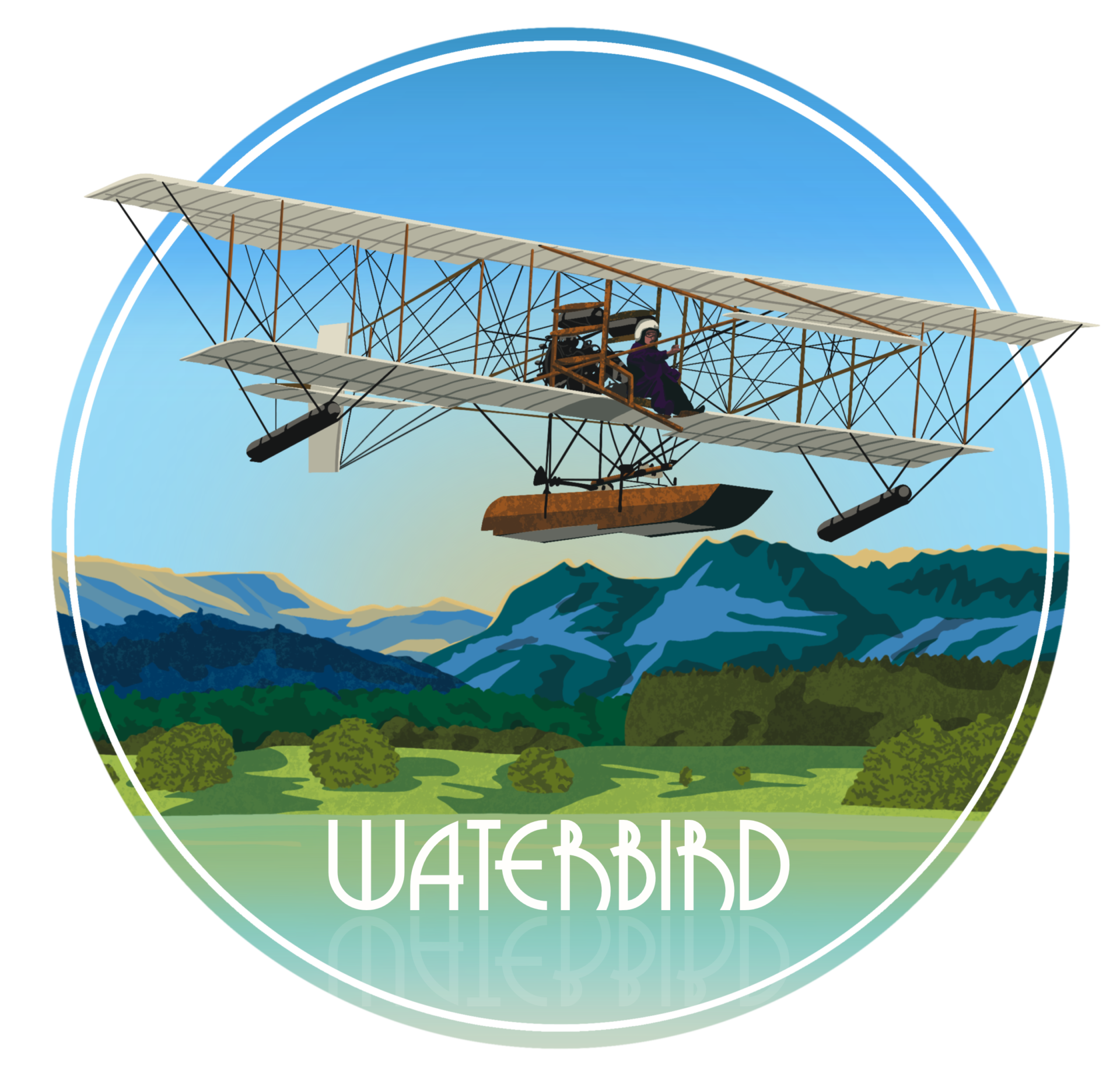

- Primarily, there was the extensive experience to draw upon at Windermere, originating with Edward Wakefield‘s vision in 1909 of flying from water and Waterbird which first flew in 1911, of Ronald Kemp, Oscar Gnosspelius and John Lankester Parker:-

- Kemp had test-flown Waterbird as a landplane at Brooklands in June 1911 and Gnosspelius No. 2 at Windermere in April 1912, becoming Chief Test Pilot for Shorts in 1914

- Gnosspelius, the only person at Windermere to design and fly their own hydro-aeroplane, was engaged in 1919 by Shorts at Rochester to take charge of the Experimental Department, and designed a Gull aeroplane built at Rochester and test-flown by Parker in 1923; despite leaving Shorts in 1925, he continued to take part in test flights until the 1930s and was involved on behalf of Shorts in local negotiations for the factory siting, and

- Parker was an instructor at Windermere 1915-1916 and succeeded Kemp as Chief Test Pilot in 1918 until 1945. (He flew the first Windermere-assembled Sunderland flying boat on its trials – please see the photo at the top of this page.)

- Windermere’s isolation away from bombing, its size and being non-tidal in contrast to the former English Electric Company Ltd’s flying boat factory (a P.5 Kingston is on the slipway, with an M3 Ayr to the right) site at the Ribble Estuary, Lytham St Annes which had not operated since 1926

- Accessibility for transportation of parts, equipment and workforce in contrast to Short Brothers & Harland Ltd at Belfast and the seaplane base at Dundee

- White Cross Bay had immediate deep water for a concrete slipway, and a location which was not exposed.

The distance of 300 yards between the Ethel Hedley Orthopaedic Hospital for Children and the factory built in 1941 (the photo was taken on 15 October) may be appreciated in this photo, taken from Orrest Head.

Being essential for war purposes, the Windermere scheme went ahead despite representations by 3 MPs from the Conservative Private Members 1922 Committee, the National Trust, the Council for the Preservation of Rural England, Westmorland County Council and Windermere Urban District Council. Complaints from the County Council and others included as to the siting of the factory near to the Hospital.

35 Sunderland IIIs were produced between September 1942 and May 1944, being DP176-200 and EJ149-158, with completed wings being delivered from Rochester. From 1944, as a Civilian Repair Organisation, repairs were carried out and about 25 refurbished.

Approximately 500 of the factory workers were housed at Calgarth, now the location of The Lakes School, which can be seen on the left here; which also shows the factory site after clearance. The factory cost £451,000 to build, the machinery and installation over £500,000, the total wages bill was £900,600, and the output in aircraft and parts was 1,180 tons, the works could have had 3,000 employees, the administrative block could have had 150 clerical workers and 800 were employed at the detail shop. The detail shop could have incorporated 2 or 3 football grounds, and a rugby match could have been staged in the hangar. The total floor area of the buildings was 233,ooo square feet.

Why the hulls of Sunderland flying boats had a ‘step’

The Sunderland III had a hull single step which was a curve upwards from the forward hull line. The first successful flight in the world of a seaplane with a step was achieved at Windermere in 1911 by Waterbird. For an explanation and the history, please see here

Water Glider

If you look closely at the front centre by the hangar doors on this photo, there you can see the Water Glider launched from the slipway in 1943 and flown by Flight Lieutenant Cooper Pattinson DFC and Flight Lieutenant Wavell Wakefield.

Taking down the buildings

It had been agreed that the buildings would be taken down as soon as the military situation made it safe to do so at the end of the war. They were removed between 1950 and 1952.

The hangar was transferred to Kirkby near Liverpool, to house a chemical works of Albright & Wilson Ltd. The office block went to the Low Miils Factory, Kendal of K Shoes Ltd in order to support expansion of production. The detail shop framework was sold for £9,500 for Slatyford Lane trolleybus depot, Newcastle upon Tyne, where it lives on: structural steel was in short supply in 1950, whilst due to restrictions on capital expenditure it did not open until 1956.

These photos were taken on 23 June 1942.

This photo was taken during the construction on 15 October 1941.

The agreement to have the buildings taken down did not include the slipway, which extends underwater for 75 yards.

Today

The site became a caravan park in 1954.

This image includes an overlay of the original buildings.